Ich bin an einem Kauf interessiert und möchte kostenlos und unverbindlich den Kontakt zum Verkäufer erhalten.

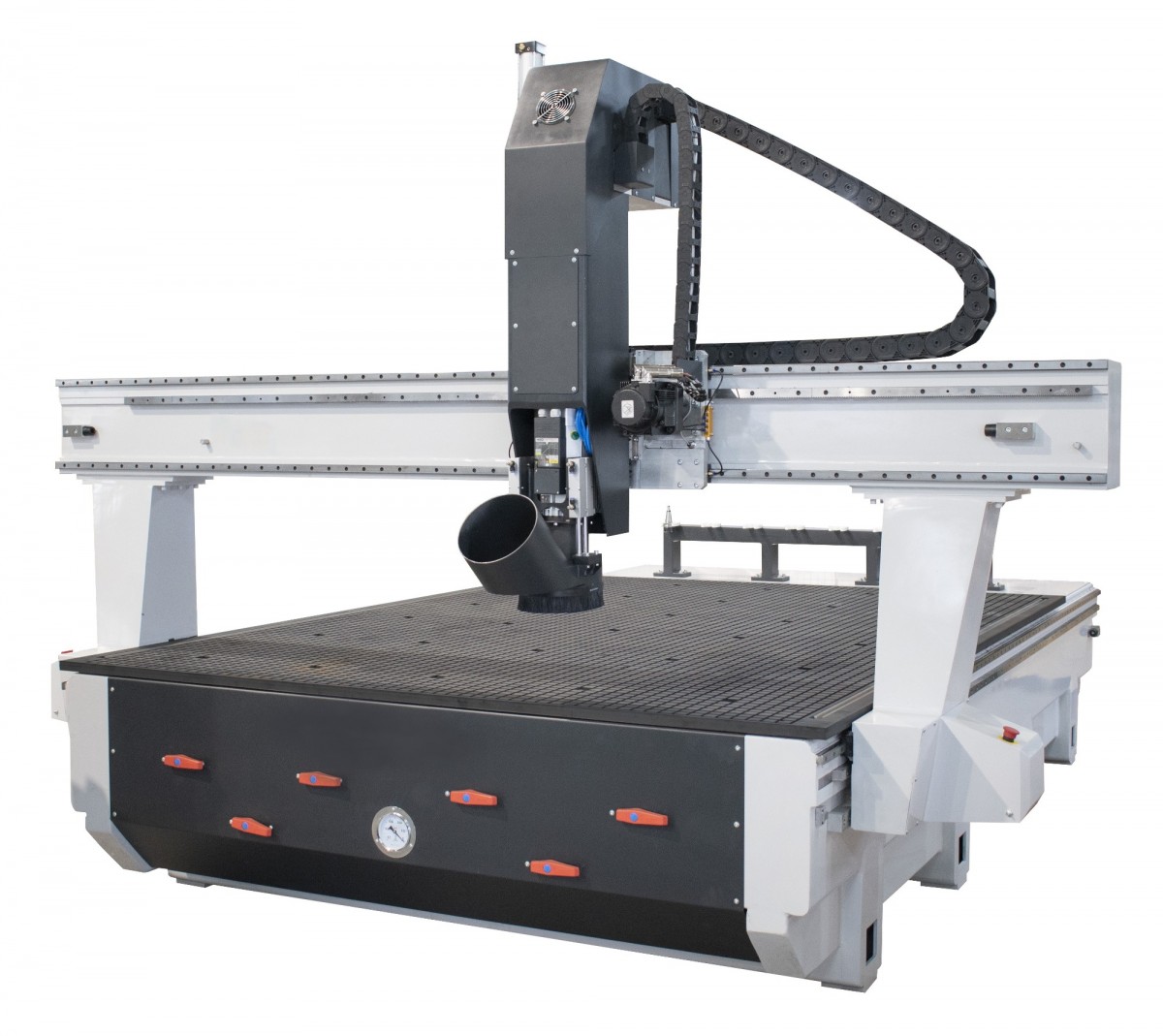

ANDERE - ATCS 2030

| Angebots-Nr.: | P22159 |

|---|---|

| Kategorie: | CNC-Fräsmaschinen |

| Hersteller: | ANDERE |

| Modell: | ATCS 2030 |

| Druckbreite: | 210 cm |

| verfügbar: | 1 Stück |

| Zustand: | Neu |

| Garantie: | 24 Monate |

| Service: | 24 Monate |

| Standort: | Polen |

| Einzelpreis zzgl. MwSt.: |

37.900,00 EUR |

| Preisart: | Verhandlungsbasis |

Beschreibung:

The ATC series machines have a specially reinforced structure, an automatic tool changing system, vacuum table and servo drives on all axes.

Machines are produced in Poland, so production process can be discused as priority, with really improved delivery time.

The CNC 2030 ATC milling plotter is a precise machine constructed completely in Poland, used for processing many kinds of materials, such as:

wood

wood-based materials (chipboard, MDF, OSB, etc.)

plastics (plexiglass, PVC, HPL, etc.)

composites (dibond, carbon, alucobond)

soft metals etc.

working area 210 x 310 [cm] (different sizes on demand)

CONSTRUCTION:

The frame of the plotter is made entirely of high-quality steel. During the production process, the frame elements are subjected to special heat treatment to avoid material tensions.

WORKING AREA:

The usable area of machine is 2100 x 3100 [mm].

MATERIAL FIXING:

The machine is equipped with a vacuum table. It is possible to install a hybrid or T-slot table.

Z AXIS RANGE AND GATE CLEARANCE:

The standard range of the Z axis is 300mm (can be increased).

DRIVES:

Machines are powered by servomotors with high resolution and power, which ensure appropriate acceleration and speed in all directions. The X and Y axes use helical racks, which ensure high durability and precision, and the Z axis is driven by a high-quality ball screw.

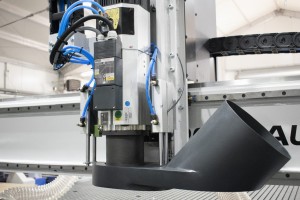

SPINDLE:

The routing tool is driven by a strong, air-cooled and durable high-class brushless 5,5 kW spindle. The spindle has high-quality cartridge bearings, very quiet and durable. The spindle operational speed ranges from 6 to 24 thousand. Rpm. The power supply is provided by an inverter, which has more power than the spindle, which protects against speed drops when working under heavy load.

TOOL MAGAZINE:

The standard equipment of the machine tool includes a linear tool magazine equipped with 6 tools with ISO30 cones.

SOFTWARE:

The machine is equipped with the CAD/CAM software in the latest version. The software enables quick and easy design elements, which the program converts into G-code toolpath. It is also possible to import files from other software.

CONTROL:

The machine is controlled using a controller that has its own processor and memory, which ensures stable and reliable operation. The machine controller has dynamic vector analysis functions, thanks to which the operation of the device is really smooth. The controller has a recovery function in case of power loss, so there is no need to initialize the whole program again. The memory built into the controller allows the machine to operate without the need to load the program each time.

Additional options (not included):

Busch or Becker vacuum pump

C axis and angular aggregates

tilting spindle

feeder and material scraper

oscillating and creasing head

chip exhaust system

oil mist

any size of work table

The price includes: machine, installation, vacuum pump, warranty and two-day training.

Transport cost needs to be defined individually.

Zugriffe

Dieses Inserat hat 131 Zugriffe.

Alle Preise zuzüglich MwSt.

Plotterboerse.com übernimmt für die Richtigkeit der Angaben keine Gewähr. Irrtümer und Zwischenverkauf vorbehalten. Das Angebot richtet sich ausschließlich an Gewerbetreibende und Freiberufler.

Vermittler-Information

Dieses Angebot wird Ihnen zur Verfügung gestellt von:

Plotterboerse.com

Gobietstr. 4

34123 Kassel